Recognizing the Value of Membrane Switch Over in Modern Electronics

Membrane switches are integral elements in modern-day electronic devices. They provide a mix of functionality and design that boosts user communication. Their lightweight and long lasting nature makes them appropriate for different applications. As industries progress, the demand for customization and advanced features expands. Recognizing how membrane changes add to development discloses their relevance fit the future of electronics. What exists in advance for this technology?

The Essentials of Membrane Change Technology

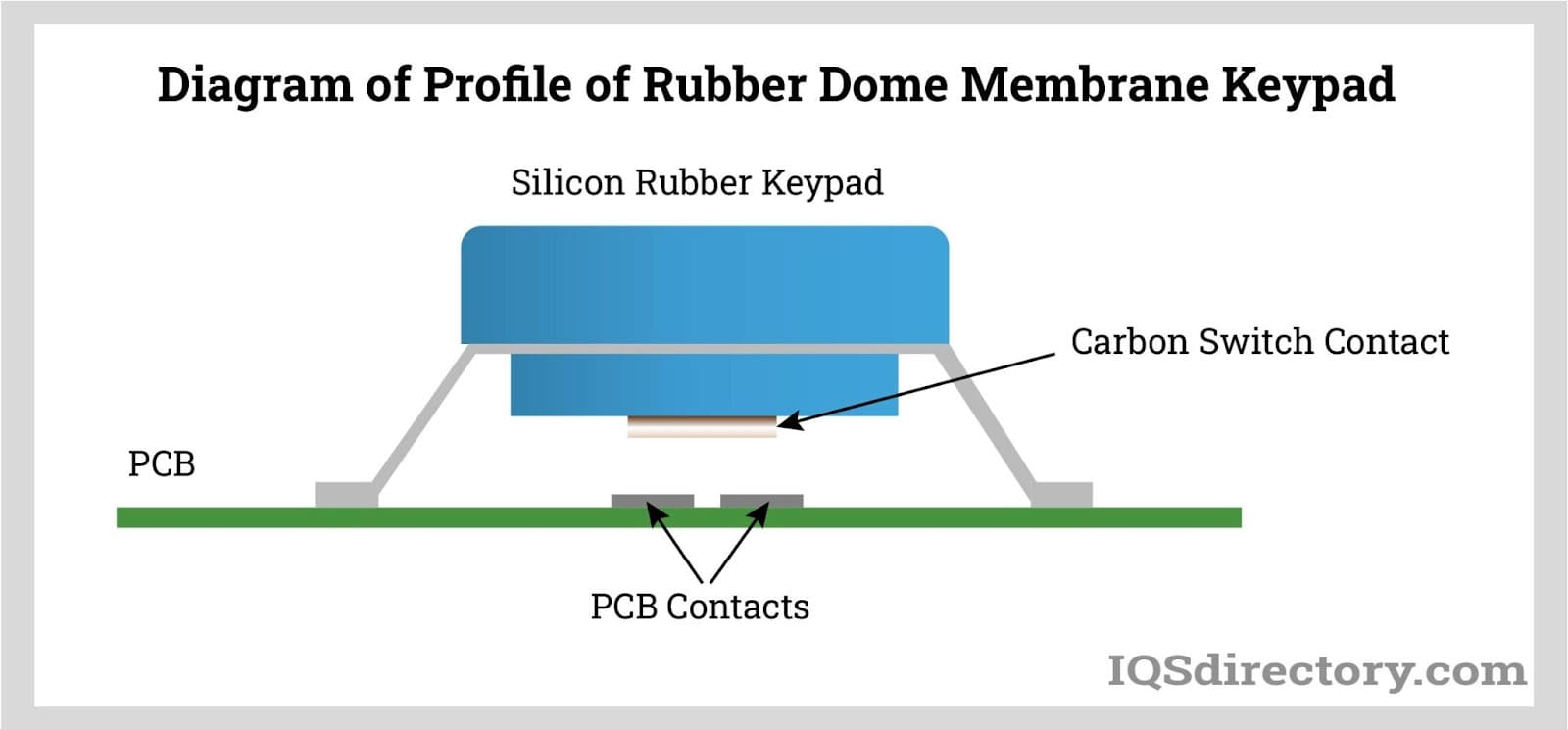

Typically overlooked, membrane layer switch innovation plays an important duty in the modern-day electronic devices landscape. These gadgets, composed of numerous layers, offer as individual interfaces for various electronic products, varying from home devices to medical equipment. A typical membrane button includes a visuals overlay, a spacer layer, and a circuit layer, which are thoroughly set up to create a useful interface.When pressure is used to the overlay, the circuit layer is completed, permitting signals to be transmitted to the tool. This technology is known for its convenience, making it possible for customization in capability, style, and form to satisfy specific individual needs. Additionally, membrane buttons are thin and light-weight, making them ideal for applications where room is a costs. Their longevity and resistance to environmental elements additionally boost their appeal, guaranteeing they can withstand severe conditions while maintaining functionality. In general, membrane switch modern technology is integral to creating efficient and easy to use electronic tools

Trick Benefits of Membrane Changes

Membrane switches over offer several vital benefits that make them a recommended option in various electronic applications. Their design permits for a compact kind aspect, allowing makers to create streamlined and light-weight tools. Furthermore, membrane layer buttons are resistant to dirt, moisture, and chemicals, which improves their toughness and durability in requiring atmospheres. The responsive comments provided by these switches can improve user experience, making them instinctive and simple to operate.Furthermore, membrane buttons can be customized with varied graphics and shades, permitting distinct branding possibilities. The manufacturing procedure is normally cost-effective, particularly for high-volume manufacturing, as it minimizes assembly time and simplifies style. Membrane layer switches over require very little upkeep, contributing to reduced total functional prices. These advantages highlight their expanding appeal in modern-day electronic devices, where reliability and straightforward interfaces are necessary.

Applications Across Various Industries

The convenience of membrane switches over allows their widespread fostering across different markets. In the clinical area, they are typically utilized in diagnostic tools and patient monitoring systems, supplying a resilient user interface resistant to contaminants. The vehicle industry makes use of membrane layer buttons for dashboard controls, improving user experience with sleek layouts that stand up to harsh problems. In consumer electronic devices, they work as control panels for gadgets such as microwaves and coffee machine, offering an easy to use interface that is simple to tidy. The aerospace industry uses membrane layer buttons in cockpit controls, where integrity and space performance are extremely important. Furthermore, the industrial sector leverages these buttons in equipment and control systems to guarantee durable operation in requiring settings. This wide series of applications emphasizes the versatility of membrane layer switches, making them indispensable elements in boosting capability and user interaction across varied technological landscapes.

Personalization and Design Versatility

Future Trends in Membrane Layer Switch Growth

Arising fads in membrane switch growth indicate a growing focus on boosted performance and combination with smart modern technologies. As consumer need for extra sophisticated electronic devices boosts, suppliers are concentrating on developing membrane layer changes that not only serve standard functional duties however likewise integrate functions like touch sensitivity, backlighting, and haptic feedback.Furthermore, advancements in materials are anticipated to enhance longevity and ecological resistance, making membrane switches over suitable for varied applications in industries such as health care, automobile, and consumer electronic devices. The assimilation of capacitive touch technology is most likely to end up being extra common, permitting sleeker designs and boosted individual interfaces. membrane switch.Additionally, the increase of the Web of Things (IoT) is motivating the advancement of membrane layer changes that can connect anonymous wirelessly with various other devices, boosting interconnectivity. Generally, the future of membrane switch technology shows up appealing, driven by technology and the quest of easy to use solutions

Often Asked Inquiries

How Do Membrane Switches Over Compare to Typical Mechanical Buttons?

Membrane layer switches, being much more space-efficient and supplying a sleek layout, comparison with traditional mechanical switches that give tactile responses. The former usually feature customizable graphics, while the last generally ensure durability and reliability in numerous applications.

What Products Are Commonly Utilized in Membrane Change Production?

Membrane switches are normally generated using materials such as polyester, polycarbonate, and published conductive inks. These products offer try here responsiveness, versatility, and longevity, making them suitable for various applications in electronic tools and user interfaces.

Can Membrane Switches Be Fixed or Recycled?

Membrane buttons can typically be fixed, particularly if minor concerns develop, such as sticky failing or surface damages. Full reuse is commonly restricted due to wear and possible deterioration of materials over time.

Just How Do Environmental Factors Influence Membrane Switch Over Performance?

Ecological aspects, such as temperature level, humidity, and direct exposure to chemicals, significantly affect membrane button efficiency. Severe problems can cause degradation, influencing responsiveness and long life, eventually compromising the performance of the tool in different applications.

What Is the Common Life-span of a Membrane Change?

The typical life-span of a membrane switch normally varies from 1 to 5 million actuations, depending on aspects such as usage frequency, ecological conditions, and the products made use of in manufacturing, affecting durability and efficiency durability. A normal membrane layer switch consists of a visuals overlay, a spacer layer, and a circuit layer, which are carefully set up to develop a useful interface - membrane switch.When stress is used to the overlay, the circuit layer is completed, enabling signals to be transmitted to the find more information gadget. The tactile comments given by these buttons can enhance user experience, making them instinctive and simple to operate.Furthermore, membrane layer buttons can be personalized with diverse graphics and colors, enabling for special branding possibilities. As consumer demand for more sophisticated digital tools increases, manufacturers are focusing on creating membrane changes that not just serve fundamental functional duties yet additionally include attributes like touch level of sensitivity, backlighting, and haptic feedback.Furthermore, advancements in products are anticipated to enhance durability and environmental resistance, making membrane switches ideal for diverse applications in markets such as medical care, auto, and customer electronics. The combination of capacitive touch modern technology is likely to become much more prevalent, enabling for sleeker designs and improved customer interfaces.Additionally, the surge of the Net of Things (IoT) is prompting the development of membrane switches over that can connect wirelessly with other devices, improving interconnectivity. Membrane switches, being a lot more space-efficient and providing a sleek layout, comparison with conventional mechanical switches that supply responsive responses